Decarbonizing the power supply for primary aluminium is critical for the sector to reach net zero. Electricity used during aluminium smelting – the process of extracting the metal from its ore – accounts for more than 60% of the industry’s carbon emissions.

It is particularly important to control the carbon emissions of China’s production of primary aluminium, which comes directly from mined ore rather than using recycled or alloy materials. Primary aluminium produced and consumed in China accounts for approximately 60% of the global market. Due to the high proportion of coal-fired energy used, 12.7 tonnes of carbon is emitted per tonne of aluminium produced in China, versus a global average of 10.3 tonnes, according to the latest figures, which cover the 2005 to 2019 period. This is why decarbonizing the power supply for Chinese primary aluminium production is critical.

- The power used to produce aluminium is a significant source of carbon emissions.

- In China – a major aluminium production hub – the government and producers are already taking steps to boost the use of greener power sources, but more must be done.

- If stakeholders across China – the government, producers, utilities, and innovators – work together, research shows renewables could account for more than 50% of the power supply for aluminium production by 2045.

China’s Energy Policies On Decarbonization

The Chinese government, like many others, is leveraging policy to influence industrial decarbonization efforts. This is happening primarily by making carbon-intensive coal power more expensive and encouraging the use of cheaper low-carbon grid power.

The government is pricing carbon to increase coal prices and by 2025 the cost of captive coal-fired power – that produced for localized, often industrial, users – is expected to exceed the cost of grid-generated power, according to industry research and Accenture’s in-house models. Aluminium companies are also likely to be included in China’s national carbon emission trading market by this time.

Further, captive coal power could start to be replaced by renewables post-2025 – once certain geographic constraints and challenges with intermittency are addressed and as the price of grid power declines. In the meantime, the government has been encouraging aluminium companies to reallocate production to the southwest region of China to take advantage of lower-cost grid power that is produced with a high proportion of renewables.

If the industry is to play its part in meeting China’s 2060 carbon neutrality targets, these efforts must continue. With this in mind, the World Economic Forum, in collaboration with Accenture, has conducted a forward-looking analysis to evaluate China’s decarbonization pathway and understand the action needed to meet the 2060 goal.

This analysis has highlighted four ways in which Chinese aluminium producers are already decarbonizing their electricity supply:

1) Reallocation of primary aluminium production capacity to areas with abundant renewables

Primary aluminium capacity is being transferred to southwest China where there are abundant hydropower resources and an energy cost advantage. From 2020 to 2025, it is expected that 2 – 3 million tonnes of primary aluminium production will be transferred annually, declining to 90,000 – 100,000 tonnes per year by 2060. Yunnan is likely to absorb the most production capacity.

2) Adjusting captive/grid power proportions

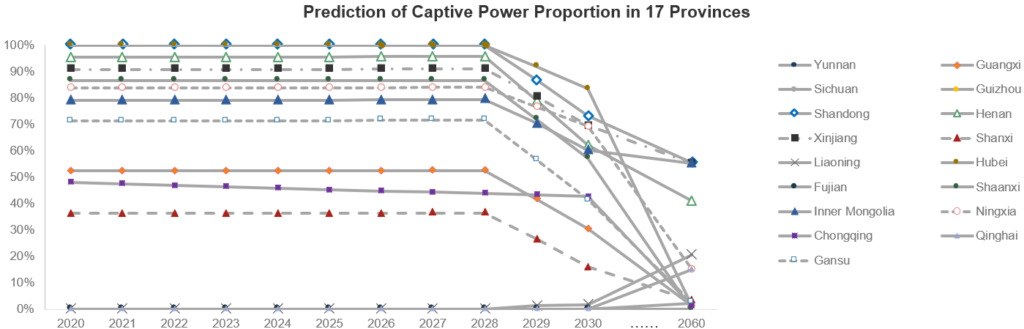

We estimate the proportion of captive power in China’s aluminium sector will fall from 60 – 70% in 2020 to 20% in 2060. In the short term, captive power will remain dominant, but it will be gradually replaced by grid power over time, except for a small number of provinces that are likely to retain captive coal-fired power plants.

Image: Accenture in-house modelling

3) The decarbonization of captive power plants

Captive renewable power technology is undergoing research and development, with only a few ongoing pilot projects in China’s aluminium sector. From 2026-2030, the total number of captive coal-fired power plants in China will gradually decrease. During this time, captive renewables will be introduced and used at a small scale. From 2031-2060, we project that captive coal-fired power will be gradually phased out and only remain in a few provinces. The application of captive renewable power will remain limited due to geographical and scale constraints.

4) The decarbonization of grid-tied power plants

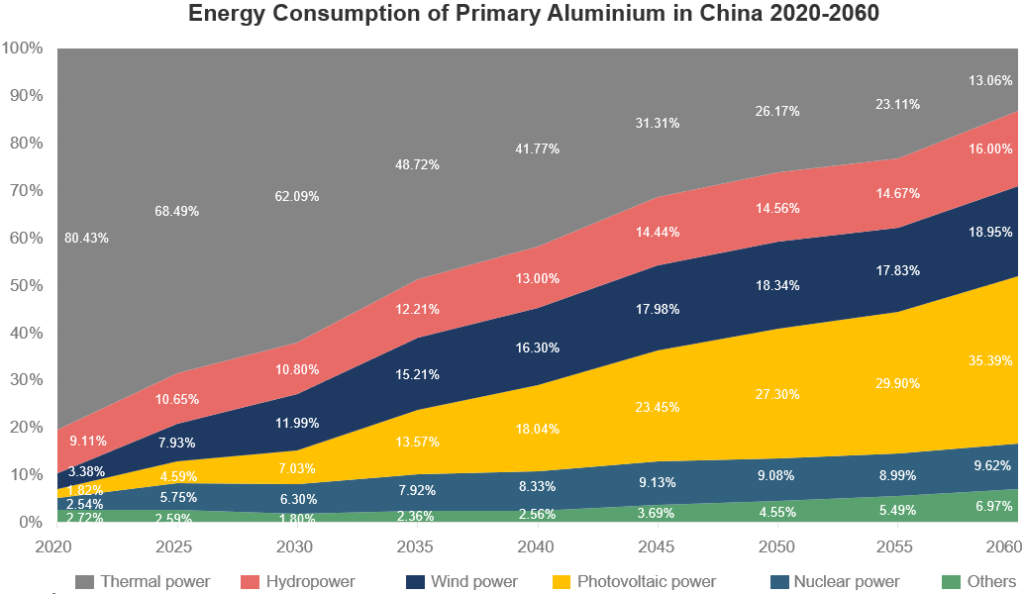

The installed capacity of renewable energy and nuclear power in China is set to increase significantly, accounting for 82.9% of all energy by 2060. Hydropower, photovoltaic, and wind power will remain the main sources of renewable energy power generation, while nuclear power will account for a relatively small proportion.

The rise of renewables

Combining the four levers above, carbon emissions for China’s aluminium sector will reach a peak of 506 million tons per year by 2028. After 2040, emissions will decrease at an average rate of 2.4% annually. By 2045, our analysis shows that renewable energy will become the main energy source for primary aluminium production, with photovoltaic power accounting for the largest proportion.

Image: Accenture in-house modelling

We are only at the start of this journey, which will consist of three phases, according to our analysis:

In 2016-2025, captive coal-fired power is still commonly used for aluminium producers due to its low price, while captive renewable power is still under development with only a few pilot projects. The cost of grid power is slightly higher than captive coal-fired power.

In 2026-2030, the price of captive coal-fired power will increase gradually due to government policies, while captive renewable power will become available at a small scale. Meanwhile, the price of grid power will become competitive and the government will encourage companies to use grid power abundant with renewable energy.

In 2031-2060, grid power will dominate China’s energy structure. Captive coal-fired power plants will be phased out and remain only in some provinces. Captive renewable power will be progressing but will still be limited by its geographical requirements. Grid power will become the main energy supplier for China’s primary aluminium industry.

The path to decarbonization

It is time to act to set China’s aluminium producers up for successful decarbonization. To do this, action is required from stakeholders across China: the government, aluminium producers, utilities, and innovators.

China’s government will need to control the nation’s total aluminium production capacity, strengthen the carbon emissions trading market and encourage the use of renewable power. Aluminium producers must eliminate outdated production capacity, shut down non-compliant captive power plants and explore the use of renewable power. Utilities must work to guarantee renewable energy power supply and explore cross-provincial green power trading methods to help companies decarbonize. Innovative technology enterprises devoted to exploring renewable energy storage and transmission technologies should partner with industry to improve the sustainability and stability of renewable energy power generation.

The dominant market position of China’s aluminium industry means its producers bear great responsibility for reducing carbon emissions. Our forecasts show a promising trajectory: by 2045 renewable sources of energy are likely to account for more than 50% of the power supply for primary aluminium production.

Jörgen Sandström Head, Transforming Industrial Ecosystems,World Economic Forum

Wen Zhang Carbon Neutrality Lead, Materials Sector,World Economic Forum

Shaun Chau ANZ Sustainability Lead, Accenture

Marc Huang Strategy & Consulting Senior Manager,Accenture Greater China

Shelia Peng Strategy & Consulting Analyst, Accenture